Design Challenge II: Forces & Materials

|

|

Prepared by : Fadhel Ali

201102569

Prepared

for: Danielle

McArthur, English for Engineering 2

|

Table

of content

|

Page:

|

Cover Sheet

|

1

|

Table of content

|

2

|

Introduction

|

3

|

The Original Mechanism

|

3

|

The Real-life Application

|

7

|

The Forces Affecting the Mechanism

|

7

|

Necessary Material

Properties for this Mechanism

|

8

|

New Material Research Findings

|

8

|

Recommendations for use

|

9

|

Conclusion

|

9

|

References

|

10

|

11

|

Introduction

Mechanisms and machines are vulnerable to be affected by

various forces, such as friction, air resistance, gravitational, attractive,

repulsive and counter forces. Forces’ effects can be either positive or

negative depending on which situation they are exerted in. For example, the

force of friction is not desirable in a gears mechanism but it is useful and

necessary in any break system.

It is important to select suitable materials in order to make

a good mechanism. Appropriate materials can be determined by defining the

functions of the mechanism and understanding the properties of materials. For

instance, if a part of a mechanism is movable, it is better to chose flexible

and malleable materials, such as aluminum and plastic.

At present, new materials play an effective role in

developing technologies. These materials give scientists more flexibility and

choices to do their research that assists in the development of

technology.

This report will focus on the modification of the mechanism

of the gripping device that was designed in a previous design challenge. Its

function was to hold and transfer objects from point to another. One of

real-life applications that were visualized is an automatic washing-machine

that can put in and pick up clothes from place to another.

The first section of the report will describe the original

mechanism. In the next section, a detailed description of the real-life

application will be provided. Then, the properties of a new material will be

explained. Finally, how this material can be used in the real-life mechanism

will be discussed.

The Original Mechanism

In the previous design challenge project, a gripping machine

was made by using simple equipment and combining simple machines together. The

device consisted of three main parts: a gripper, a horizontal motion system and

a vertical motion system. In these three parts, three different simple machines

were used.

In the first moving part (the gripper), a lever simple

machine was used in order to open and close it. By putting an effort on the

handle of the gripper, the gripper arm moved in the opposite direction of press

which made it open. On the other hand, by removing the effort from the handles,

it locked. See figure 1.

Figure 1. How to lock and release the load.

Figure 2. The horizontal

motion arm.

Figure

3. The crank mechanism

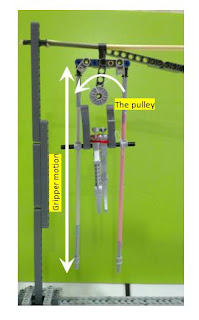

Finally, in order to move the load up and down, the pulley

system was used. The two ends of the rope of the pulley were tied to two

sliding pieces and by rotating the pulley, the gripper moved vertically. See

figure 4.

Figure 4. The vertical motion mechanism

(pulley system).

The Real-life Application

The imagined real-life application is two arms that would be

attached to a washing machine in order to assist in the process of picking up

and putting clothes from place to the washing machine or the opposite. The same

technique of horizontal motion of the previous mechanism would be used in the

visualized device but with using electrical motor. In addition, a pneumatic

system would be used rather than the pulley system in the vertical motion mechanism.

Furthermore, all techniques would be controlled by using a programmable logic

controller (PLC).

It would be a useful application because the process of the washing

machine would be in a continuous sequence. It would be also helpful for hotels and

laundries because it would assist to minimize the pays of workers due to the

fact that it would not be needed for workers to fill the washing machine with clothes

or to re-operate it after each wash. Additionally, to make the device work properly

it is important to determine the real life of the device. However, the scale of

the arms would depend on the size of the washing machine.

The

Forces Affecting the Mechanism

One of forces that would affect the mechanism is a centrifugal force.

When an object is rotating, there is a centripetal force that attracts the

object to the center of rotation. Newton’s third law of motion says that every

action has an equal reaction toward the opposite direction. As a result,

centrifugal force occurs as a reaction of the centripetal force and attempt to

make the object repel from the center of rotation. ("Centripetal force and

centrifugal force," 2013).

While the

washing machine is running, the inside part of it is rotating. Consequently, a

centrifugal force would appear as a reaction to the centripetal force. As a

result of the centrifugal force, the washing machine would vibrate.

Necessary

Material Properties for this Mechanism

In this

mechanism there would be fixed and moving parts. For the fixed part -which

would be the slider path- it would be better to build it from a tough material

because it would carry the two arms. In this case it is also necessary to use a

malleable material to adjust the slider (the path) to make it fit with the

sliding piece. Malleability is the amount of deformation that materials can be resisted

without braking. (Bell, 2012)

Furthermore, for moving parts- the gripper and sliding

pieces- it would be preferred to use corrosion resistant and light materials in

order to make the motion more easy, flexible and smooth.

New

Material Research Findings

Carbon fiber is a new material that belongs

to the polymers family and it consists of fibers and polymers of graphite. In

1800’s carbon fiber was discovered by Thomas Edison but it had a low tensile

strength and a very good heat resistant. Carbon fibers spread out when a high

tensile strength was discovered on 1950’s by Rayon. ("The history of

carbon fiber," n.d. and "High performance carbon," 2003)

Carbon fiber

has many properties that make it popular in the engineering field, such as high

stiffness, high tensile strength, light weight, high chemical resistance, high

temperature tolerance and low thermal expansion. ("Carbon (fiber),"

2013 ). Its light weight and stiffness would be useful in building the

mechanism.

Its stiffness is gained from its chemical structure. “It is

made of carbon crystals aligned in the long axis. These honeycomb shaped

crystals organize themselves in long flattened ribbons. This crystal alignment

makes the fiber strong”. ("Carbon

fiber characteristics, n.d." )

Recommendations

for Use

Carbon fiber would be a suitable

material to use in making the mechanism. Its properties could be useful for the

mechanisms especially its light weight and stiffness. The mechanism would gain

the advantages of transportation possibility -that would allow to the user to

separate and attach the two arms easily- and high strength.

Carbon fiber could be used in making the slider path- which would

carry the two arms- because it would be strong enough to lift the two arms due

to its high stiffness. Furthermore, carbon fiber would be also appropriate for building

the two arms of the mechanism due to its light weight which make them transport

easily.

Conclusion

To conclude, a real-life application for the previous

challenge project was visualized. In addition, this report described the

imagined vision of the application by explaining the uses of the mechanism, the

forces that could affect it and the properties of the materials that could be

used for it.

In the second part of findings, the report focused on carbon

fiber’s properties, history and family. Furthermore, an explanation of how

carbon fiber could be used in the mechanism was provided. Nowadays the engineering

field is reflecting the significant importance of innovation by providing new

ideas in different ways in order to create an easy and simple life. Finally, to

cover people’s needs and to have a comfortable living, more and more new

materials are discovered.

Appendix A

Figure 5. The original mechanism

References

Bell, T. (2012). Malleability.

Retrieved from http://metals.about.com/od/metallurgy/a/Malleability.htm

Carbon fiber

characteristics. (n.d.). Retrieved from http://www.christinedemerchant.com/carboncharacteristics.html

Carbon (fiber). (2013 , May 30 ). Retrieved from

http://en.wikipedia.org/wiki/Carbon_(fiber)

Centripetal force and centrifugal force. (2013). Retrieved

from http://www.infoplease.com

/encyclopedia/science/centripetal-force-centrifugal-force.html

High performance carbon fibers. (2003, September 17). Retrieved from http://portal.acs.org

/portal/acs/corg/content?_nfpb=true&_pageLabel=PP_SUPERARTICLE&node_id=717&use_sec=false&sec_url_var=region1&__uuid=3bcbdb4a-7a52-4a8a-8ed1-c2e0960d1ca1

The history of

carbon fiber. (n.d.). Retrieved from

http://www.hj3.com/company/history-of-carbon-fiber/

(2012, July 18).

crank-animation [Web Photo]. Retrieved from http://www.google.com.bh/ url?sa=i&rct=j&q=&esrc=s&frm=1&source=images&cd=&docid=nFpwlzKBz2oQJM&tbnid=-arNFPA4NMPxRM:&ved=&url=http://www.explainthatstuff.com/cranks-and-cams.html&ei=KWPDUbuHOcuWhQed54Aw&psig=AFQjCNE2ECMbGNV9PNVkilLCSNxHDHsTrg&ust=1371845802414021